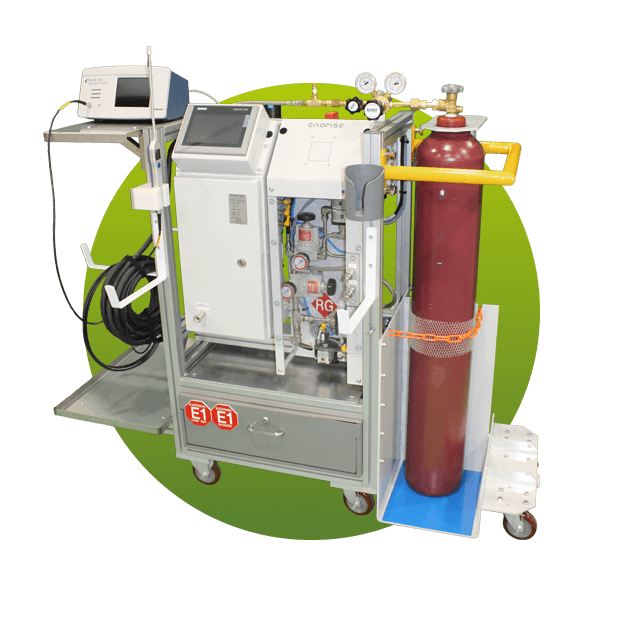

Leak Test Cart

Mobile leak testing solution for industrial environments

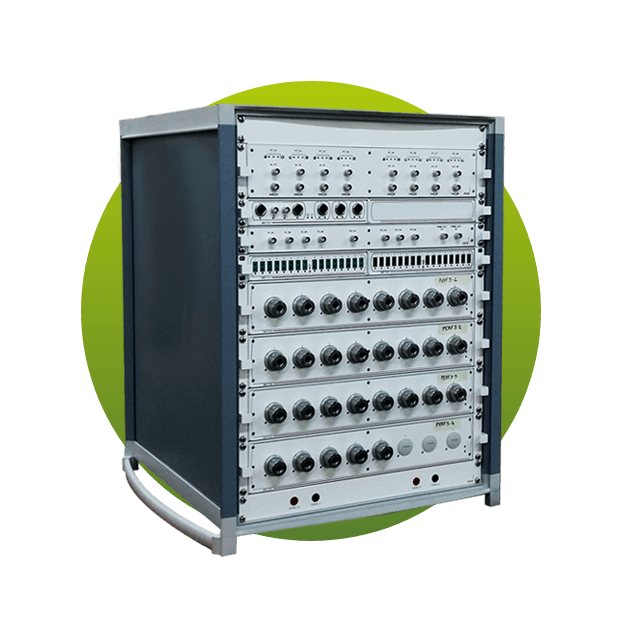

The ENORISE Leak Test Cart is a mobile leak testing solution designed for industrial applications requiring accuracy, safety, and operational flexibility. Developed to support both manual and semi-automatic leak testing, it allows manufacturers, test engineers, and production teams to perform reliable leak measurements directly in workshops, laboratories, or production areas.

Why choose a mass flow leak testing system?

The ENORISE Leak Test Cart has been engineered to combine measurement accuracy, operator safety, and mobility in a compact industrial design. Its robust aluminum structure ensures long-term durability, while its ergonomic layout allows operators to work efficiently and safely.

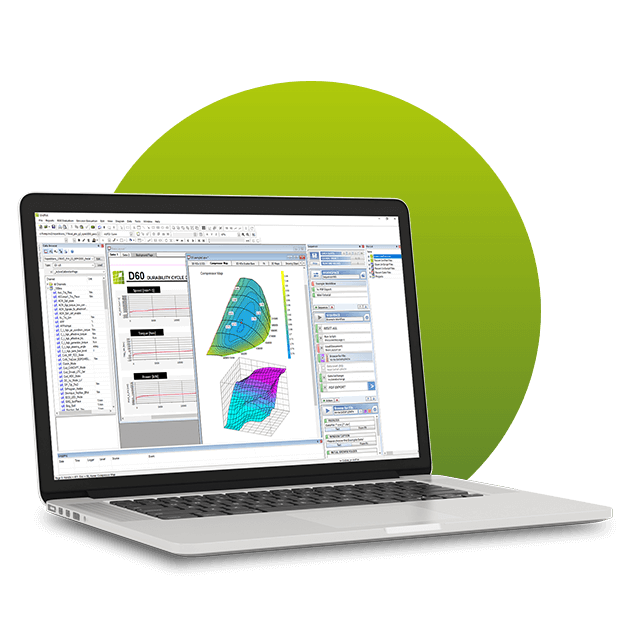

Thanks to its real-time leak measurement capability, users can immediately identify leak rates and make fast, informed decisions during testing phases. This significantly reduces test cycle time and improves overall productivity.

Benefits

- Robust construction with extruded aluminum frame

- Integrated manual or semi-automatic controls

- High accuracy instrumentation and regulators

- Comprehensive safety features including lock-out valves and GFCI protection

- Easy mobility with casters and ergonomic handle

Leak test cart configurations for manual, vacuum and semi-automatic testing

The Leak Test Cart is based on the mass flow leak testing method, a proven technique widely used in industrial leak detection. The ENORISE Leak Test Cart is available in several clearly defined configurations, allowing it to be adapted to a wide range of industrial leak testing scenarios.

Manual Testing

The single or dual circuit manual configuration is designed for applications requiring flexible and precise leak testing operations in development, production or quality control environments. It allows operators to perform controlled leak measurements using a reliable industrial leak testing system.

Vacuum Testing

For applications involving components that must be tested under negative pressure, the vacuum configuration enables accurate vacuum leak testing. This solution is particularly suited for industrial parts where pressure-based testing is not feasible.

Semi-automatic Testing

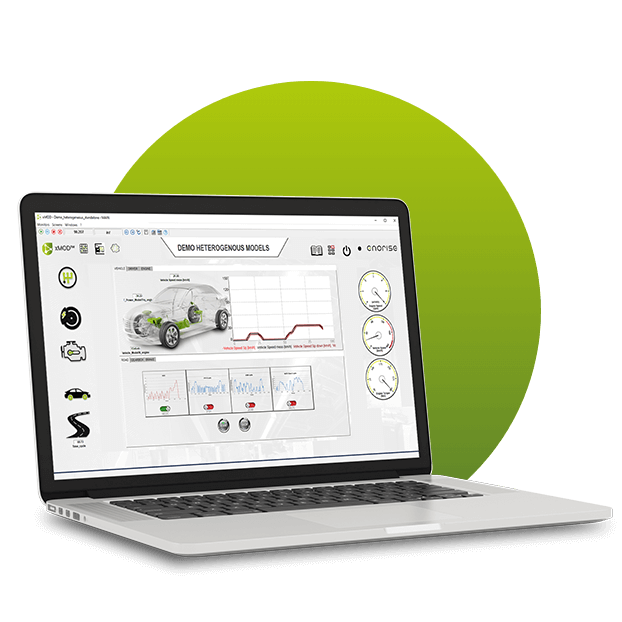

To improve repeatability and reduce operator dependency, the semi-automatic configuration integrates PLC-based control and an intuitive HMI. This version is especially adapted to production leak testing where consistency, efficiency and traceability are critical.

Typical applications of the ENORISE leak test cart

The ENORISE Leak Test Cart is available in multiple configurations to adapt to different testing strategies and production constraints.

Manual configurations are ideal for controlled leak testing operations requiring flexibility and operator interaction. For higher repeatability and reduced operator dependency, semi-automatic versions integrate PLC control and an intuitive HMI interface.

For components requiring negative pressure testing, a dedicated vacuum configuration is available, enabling reliable vacuum-based leak detection.

Advanced leak detection with trace gas solutions

To address more advanced testing needs, the Leak Test Cart can be equipped with optional trace gas solutions. These options allow the use of hydrogen or helium leak detection, making the system suitable for high-sensitivity leak testing applications.

Integrated bottle storage and trace gas filling capabilities ensure safe handling and efficient operation in industrial environments.

Industrial design focused on safety, mobility and reliability

Safety and usability are central to the design of the ENORISE Leak Test Cart. Integrated safety features protect both operators and equipment, while the mobile design allows the cart to be easily moved between workstations without compromising stability or performance.

The overall layout has been optimized to ensure intuitive operation, easy access to components, and efficient maintenance over the system’s lifecycle.

Contact our Leak Test Cart experts